Boiler and Condenser Tube Cleaning Equipment |

| |

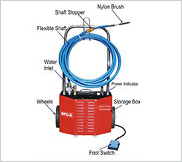

| Electric Tube Cleaners |

| |

|

In condenser tube cleaners, tube cleaning equipments, condenser tube cleaning, electric tube cleaners and pneumatic tube cleaners, the brushes or other cleaning tools are rotated through a tube at tip of flexible shaft. Simultaneously water gets injected, hence loosen deposits leaving tubes cleaned. Flexible shafts ensure use in bent tubes.

All models like condenser tube cleaners, electric tube cleaners, pneumatic tube cleaners are consist of tool storage box, single direction foot switch, mobile dolly.

2 direction foot switch is optional.

All units are available with following specifications :

• 115 v 60 Hz, 115 v 50 Hz - 9 Amps

• 220 v 60 Hz, 220 v 50 Hz - 4.5 Amps

• While ordering, please mention electric specifications. |

|

| |

Model No |

Motor |

Tube ID |

Speed RPM |

HP. |

kw |

Inch |

Mm. |

NPC-2 |

0.50 |

0.40 |

1/4 -1 |

6.4 - 25.4 |

870 |

NPC-3 |

0.75 |

0.60 |

1/4 -1 |

6.4 - 25.4 |

870 |

NPC-4 |

1.00 |

0.75 |

1 & up |

25.4 & up |

1740 |

NPC-5 |

2.00 |

1.50 |

1 & up |

25.4 & up |

1740 |

|

|

| |

| ......................................................................................................................................................................................................................................... |

| |

| Portable Electrical Tube Cleaners |

| |

|

NPC- P is a portable machine which can be carried by technician on the move. Flexible shaft rotates at speed of 1740 rpm and water gets injected simultaneously through the nylon casing to the cleaning tool. As the tool removes the deposits, the water flow flushes them out. A solenoid valve ensures that water flows only when machine is running..

All units are available with following specifications :

• 115 v 60 Hz, 115 v 50 Hz - 9 Amps

• 220 v 60 Hz, 220 v 50 Hz - 4.5 Amps

• While ordering, please mention electric specifications. |

|

| |

| ......................................................................................................................................................................................................................................... |

| |

| Chiller Tube Cleaning Equipments |

| |

|

Model No. BPC3-45 chiller tube cleaning system uses a 3/4 HP motor for tougher deposits. A 2 directions foot switch is provided for cleaning internally enhanced tubes.

CONTENTS:

* BPC-3 Tube cleaners-1

* NFSC-703-45 Flexible Shafts-2

* Nylon Brush (Specify Size)- 25

* Two Direction Foot Switch-1

* Repairing kit for flexible shaft NFSC-703 consisting of 4 drive couplings, 4 tool end couplings, 1 crimping tool with punch, 1 flexible shafts lubricator, & 2 bottles of lubricant Tubes. |

|

| |

| ......................................................................................................................................................................................................................................... |

| |

| Pneumatic Tube Cleaners |

| |

|

Features :

* Shock Resistant - Excellent for applications where using electric equipment is hazardous.

* Speed/Torque control - Shaft rotation can be set at optimum speed for each application.

* Versatile - Interchangeability of different size flexible shafts and cleaning tools.

* No Tooling - Quick disconnect for flexible shaft.

* Easy maneuverability - Large Wheels.

* Cleanliness - Foot pedal for operator convenience to activate shaft rotation and water flow to reduced water consumption and cleaner working area.

* Time Saving - Simultaneous water flush to remove deposits from tubes

|

|

| |

Tube ID Range |

Tube Cleaner Model No. |

Motor Power |

Motor Speed RPM |

Weight |

Dimensions |

Mm. |

Inch |

HP |

KW |

Lbs. |

Kg. |

High |

Wide |

Deep |

6.4 & UP |

1/4 & UP |

NPTC-400 |

4 |

3 |

0-3000 |

64 |

29 |

38" (975 mm) |

22" (560 mm) |

16" (406 mm) |

|

| |

| ......................................................................................................................................................................................................................................... |

| |

| Tube Cleaning Accessories |

| |

|

While ordering flexible shafts & accessories, each item should be ordered for specific tube/pipes size or size range.

Stainless steel inner core ensures our shafts have longest life, resistance to corrosion,

To order flexible shaft (s) determine tube l.d. & Length of longest tube (s). Order flexible shaft(s) to correspond with tube I. D.(s), & length. Please ask for special or longer length. |

|

| |

Tube ID Range |

Flexible Shaft |

Flexible shaft Length |

Nylon |

Casing O. D. |

Inner Core O. D. |

Tool End |

Mm. |

Inch |

Model No. |

Feet |

Mtrs. |

Inch |

Mm |

Inch |

Mm |

Thread |

6.4-9.5 |

1/4-3/8 |

NFSC-701-12 |

12 |

3.7 |

1/4 |

6.4 |

1/8 |

3.2 |

8-32 F |

|

|

NFSC-701-25 |

25 |

7.6 |

|

|

|

|

|

|

|

NFSC-702-12 |

12 |

3.7 |

|

|

|

|

|

|

|

NFSC-702-17 |

17 |

5.2 |

|

|

|

|

|

11.1-12.7 |

7/16-1/2 |

NFSC-702-25 |

25 |

7.6 |

3/8 |

9.5 |

1/4 |

6.4 |

1/4-28 F |

|

|

NFSC-702-35 |

35 |

10.7 |

|

|

|

|

|

|

|

NFSC-702-45 |

45 |

13.7 |

|

|

|

|

|

|

|

NFSC-703-12 |

12 |

3.7 |

|

|

|

|

|

|

|

NFSC-703-17 |

17 |

5.2 |

|

|

|

|

|

|

|

NFSC-703-25 |

25 |

7.6 |

|

|

|

|

|

14.3-25.4 |

9/16/1 |

NFSC-703-35 |

35 |

10.7 |

1/2 |

12.7 |

5/16 |

7.9 |

1/4-28 F |

|

|

NFSC-703-45 |

45 |

13.7 |

|

|

|

|

|

|

|

NFSC-703-60 |

60 |

18.3 |

|

|

|

|

|

|

|

NFSC-703-75 |

75 |

22.9

|

|

|

|

|

|

|

| |

|

| Back |

| |