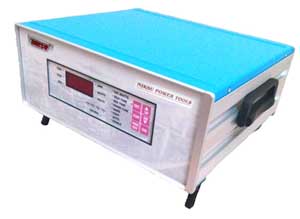

Electronics Torque Controller Wattage Based

• Fully Solid State Design.

• Accurately Calibrated Digitally Torque setting.

• Connected Drive is automatically recognised & indicated by means of LED indicator on the Torque

• Controller panel.

• Slow start has been provided to all the drives for safety.

• Trip, Reverse & Pause time are adjustable.

• Manual Reverse provided in case of emergency.

• Trigger (Hand) & foot mods are avialable.

• LED on the panel board indicates the forward, reverse or trip condition of drive.

• MCB has been provided for he Safety.

Electric Drives use with Torque Controller For Expansion

Features :

Branded Heavy Duty Motors.

High Torque to Weight Ratio.

We are offering Electrically Torque Controller

Features :

01. Fully Solid State Design - no moving parts - no wear and tear of parts - no noise - consequently long life.

02.

Uses one main circuit board for easy maintenance.

03.

Uses the latest micro-controller chip for control functions.

04.

Accurately calibrated digital torque settings with a resolution of 1 watt makes torque settings accurate and can be easily reproduced for identical results.

05.

Soft start has been provided for all drives. This feature reduces starting currents in the drive. As a result, life of carbon brushes & drive increases.

06

Connected drive is automatically recognised & indicated by means of LED on the torque controller.

07.

Torque setting arranged in four different ranges to suit four different drives. Appropriate wattage range is automatically selected for the connected drive, hence drives can not be abused or overused.

08.

Actual drive wattage (torque) is displayed. Set wattage (torque), drive current and line voltage can be seen by press of a button.

09.

Trip time adjustable from ( 0.1 sec to 10 secs. )

10.

Adjustable reverse time from ( 1 sec to 100 secs.)

11.

Pause time (time interval between cycles) adjustable from ( 1 sec to 100 secs.)

12.

Manual reverse by push button, in case of emergency.

13.

Drive Speed adjustable in reverse rotation.

14.

Hand (trigger) mode or foot switch mode, both are available.

15.

Expansions can be carried out either in single cycle mode or auto repeat mode.

16.

LED indicators provided for forward, reverse & trip conditions of drive.

17.

MCB has been provided to protect the and drives against over current by short circuits.

18.

Plug in type of PCBs reduce down time to minimum during trouble shooting.

19.

All the spares inside the panel viz : PCBs, Transformers, CT, Relays DPM etc. can be replaced by use of only a screw driver.

20.

Superior SCR technology has been incorporated rather than triacs. SCRS have much better voltage, current & dv/dt ratings than triacs. This leads to greater reliability & the power circuit becomes almost failsafe.

21.

Niksu has over 1000 TCW Torque Controllers in active use worldwide since its inception in year 2000.

Model No. |

Voltage Single Phase 50/60 Hz |

Weight (kg) |

TCW-110 |

110 V |

11.0 |

TCW-230 |

230 V |

11.0 |

Note : Voltage Stabilizers for use with TCW torque controllers. All TCW torque controllers are supplied with operation manuals.